Making moulds and tools are expensive, and their service life can be shortened by wear & tear, damage and corrosion. Laser welding can significantly increase the life of molds and tools. With the help of laser deposition welding, user can easily modify design/change design, so that an old mold will not have to be replaced. Laser systems from SIL feature excellent performance and flexibility. With our robust, high-performance laser welding devices, we provide you a machine that allows complicated structure that are difficult or impossible with traditional welding technologies, even in the immediate vicinity of sensitive materials, such as plastic or glass. The good control of laser energy and exposure time allows welding of metallic materials with high melting temperatures and high thermal conductivity. It can even be used to weld different metals.

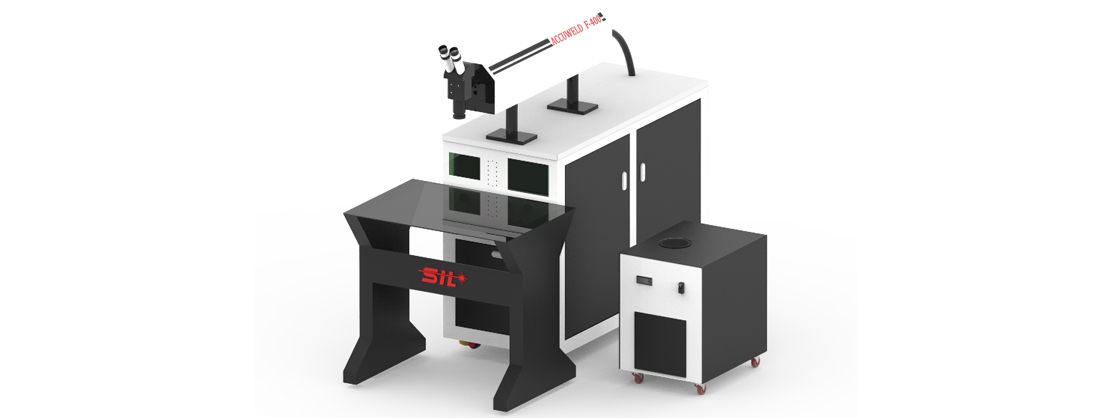

Application determines the choice of a laser source. SIL has Nd:YAG and Fiber Sources. Based on the application, we can therefore advise you in finding the best solution for you.

| Model | SIL – 200 W / 600 W |

| Average laser power | 240 / 640 W |

| Max energy of single pulse | 90J / 120J |

| Laser wavelength | 1064 nm |

| Pulse width | 0.2 to 20 ms |

| Laser welding frequency | 1 – 100 Hz |

| Spot size range | 0.2 – 2 mm |

| Welding wire | 0.1-0.8 mm |

| Line Voltage | 220VAC/38 0VAC ± 10%/50-60Hz / 30A |

| Power consumption | ≤ 6kW/12kW |

| Water pressure protection | ≤ 0.025 Mpa |

| Cooling water temperature | ≤ 35 degrees |

| Temperature protection | 45 degrees |

| Cooling water flow | 33L/min |

| Weight | ≤ 400kg |

| Cooling way | Water cooling |

| Laser type | Pulse |